Engineering

Because at PTM Corporation we offer you complete design solutions, we are able to go from concept to realization. As an illustration, your idea or design may start as something very simple; an idea sketched on a beverage napkin for example.

What’s more, our experienced design staff will analyze the need and provide solid engineering experience needed to ensure that all aspects of the manufacturing process are reviewed for feasibility and cost versus spend benefit.

To explain, our systematic approach will consider the application, material required, the number of pieces needed and several other key factors. Once completed, we will make our design recommendations for both the product and tooling to manufacture it. Most important, our goal is to maximize the ROI of your spent dollars both in the design and while the part is in production.

Product Design

PTM is a Great Extention of Your Engineering Department

At PTM Corporation we provide a commitment to product design. With many years of manufacturing experience, we know the importance of the involvement in projects as early as possible.

For example, if you involve the PTM Team in the early design/development stages, because of our vast knowledge of metal stamping experience, we will provide you with the best solutions based on the needs of your application.

In fact, simply provide your concept and surrounding date. Then describe what needs to be accomplished, and our design team will take it from there.

Come see the difference our experience can make on your next project!

The benefits of having PTM Corporation involved early in your product design are:

Low cost FDM 3D sample for initial design reviews

Quick turnaround from conception to completion

Minimize material requirements and manufacturability

Improved quality and functionality

Minimize Tooling costs

Prototyping

Benefit from cross functional campus relationships with the tooling and production departments.

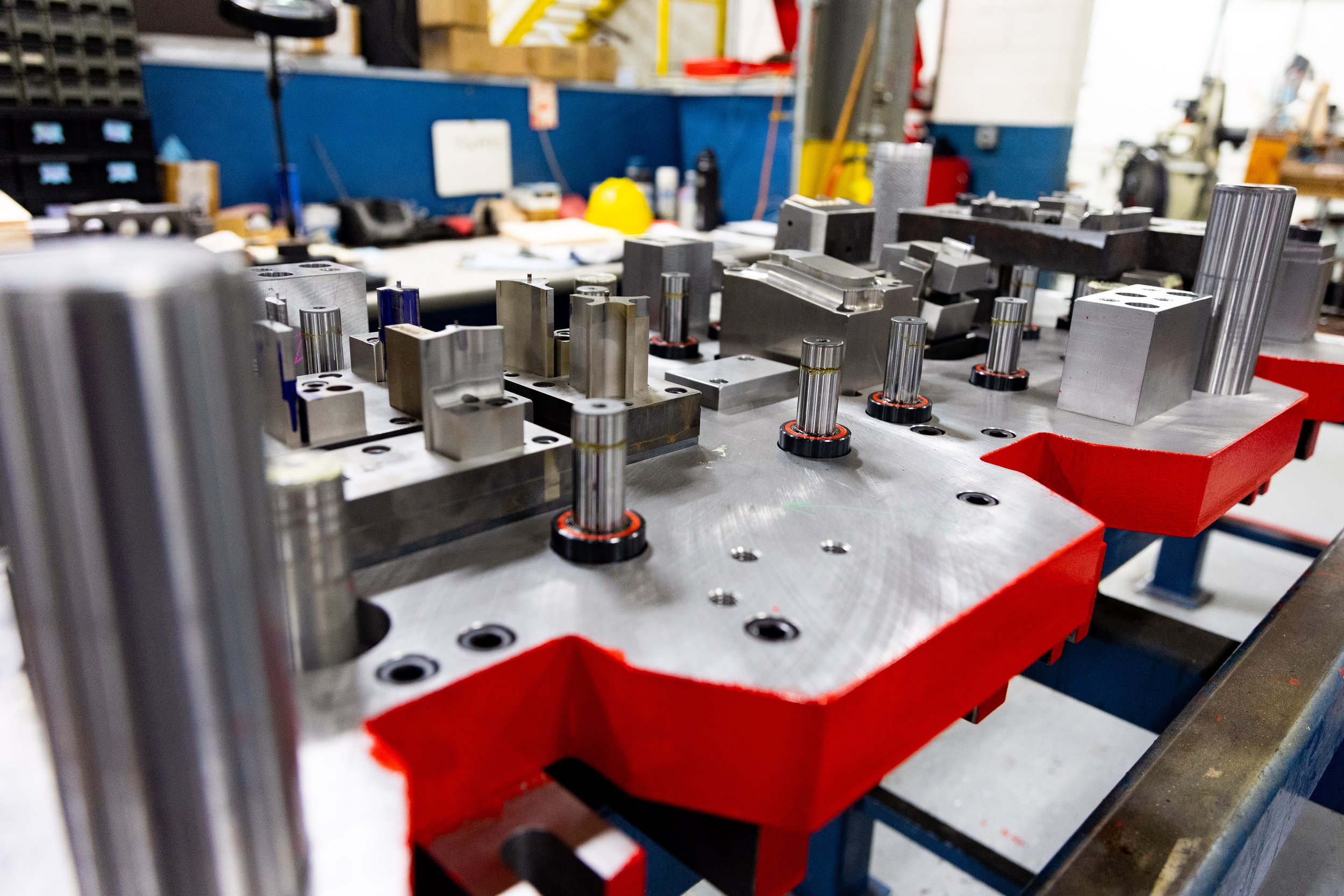

Tool Design & Build

We marry state of the art software to our CNC machining centers, throw in “lights out” wire EDM machines, and add automated grinding to get your tooling built quickly and accurately.

At this stage of the game, time really is money! By keeping our tool builds in house, we control not only the time line, but also the quality of the tool and most importantly the cost.

From the simplest compound die, all the way up to 4 piece kirksite monsters, our team of professionals will build, test and deliver as promised. Have a look through the link below for more details and give us a call for your next build!

Advanced CAD Systems

At PTM Corporation we work with the most advanced CAD systems available. For instance, we use Catia V5, which is used by many leading industry manufacturers.

Likewise, KeyCreator is another program we utilize to aid in product development along with production and prototype tooling design. These programs give PTM Corporation the edge over the competition. Therefore this enables us to create concept models in a very short amount of time. Subsequently, helping us and our customers meet the short deadlines which are so common in our industry. PTM Corporation can accept and send native formats from many of the familiar CAD systems for seamless data transfer.

Import / Export Capabilities:

With Spinfire we can import, read and translate multiple native CAD formats.

Utilizing the most advance CAD Systems

Nx

Solidworks

Catia

Visi 3D

Spinfire Ultimate

Autoform

Polyworks

MasterCAM

WorkNC

Keycreator

Cenit Fastsuite

Paint Tool Design & Build

PTM Corporation is an innovative leader in paint tool designs for automotive assembly plants across the globe. We have many years of experience and knowledge with all phases of paint process tooling, solutions and builds. Our engineering group works directly with our customers to fully understand the processing goals. This enables us to design and develop the right tool for your application. We are a full service supplier from the first concept part through final tool build.

PTM Corporation pioneered the well known “paint clip” which revolutionized the old jig or fixture type tools that were commonly used to hold doors in position through the paint process. It has been consistently proven that using the PTM Corporation paint clip benefits many hidden factors resulting in lower overall processing cost and improving paint quality.

We understand making a process change from fixture style tools to our Cricket Clips can be a huge challenge. Our team will prototype any new design so that it can be thoroughly tested before making any process changes. Potential production costs and piece price estimates can then be generated so the ROI on the change can be determined. Our goal is to maximize the efficiency and productivity of our client's team!