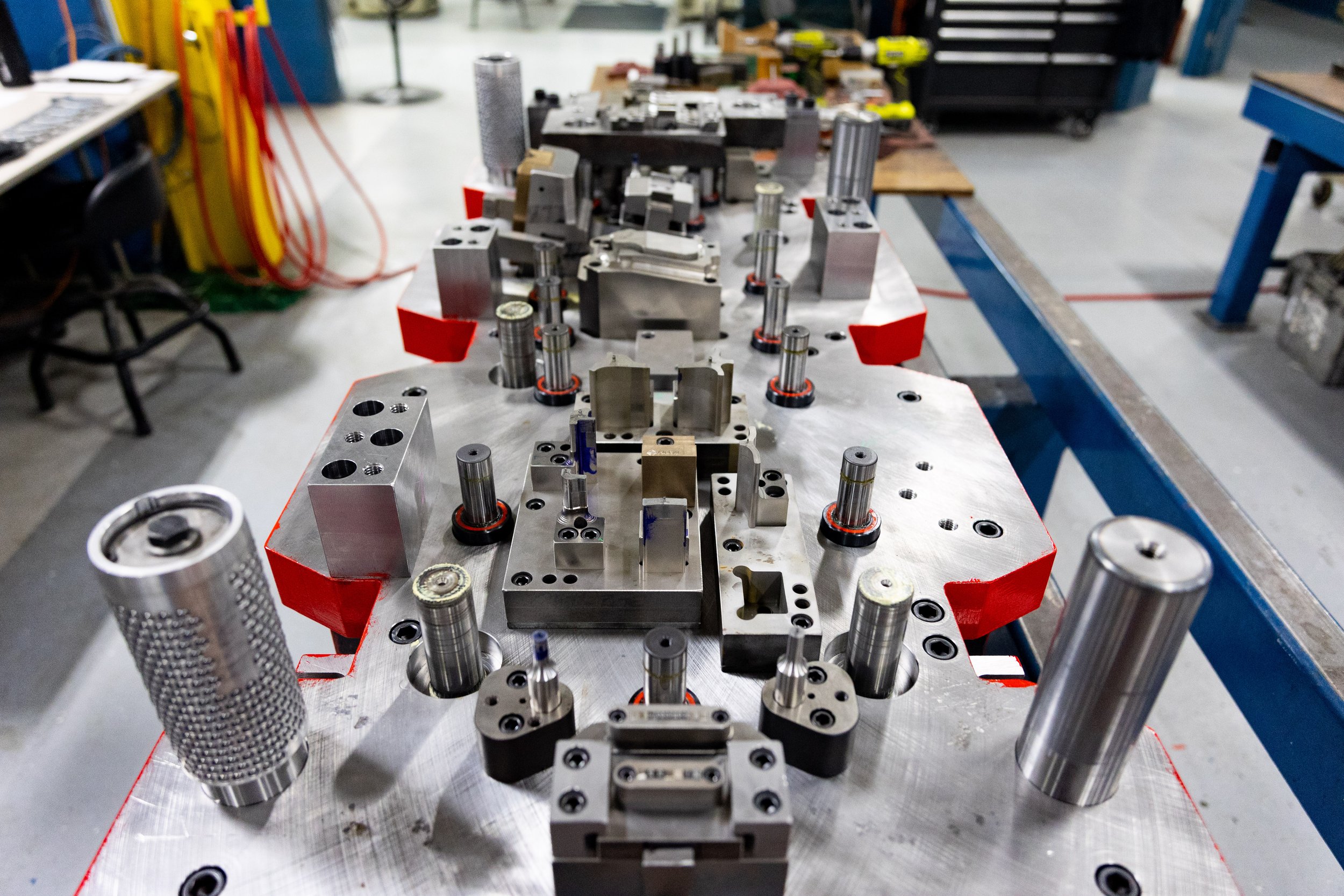

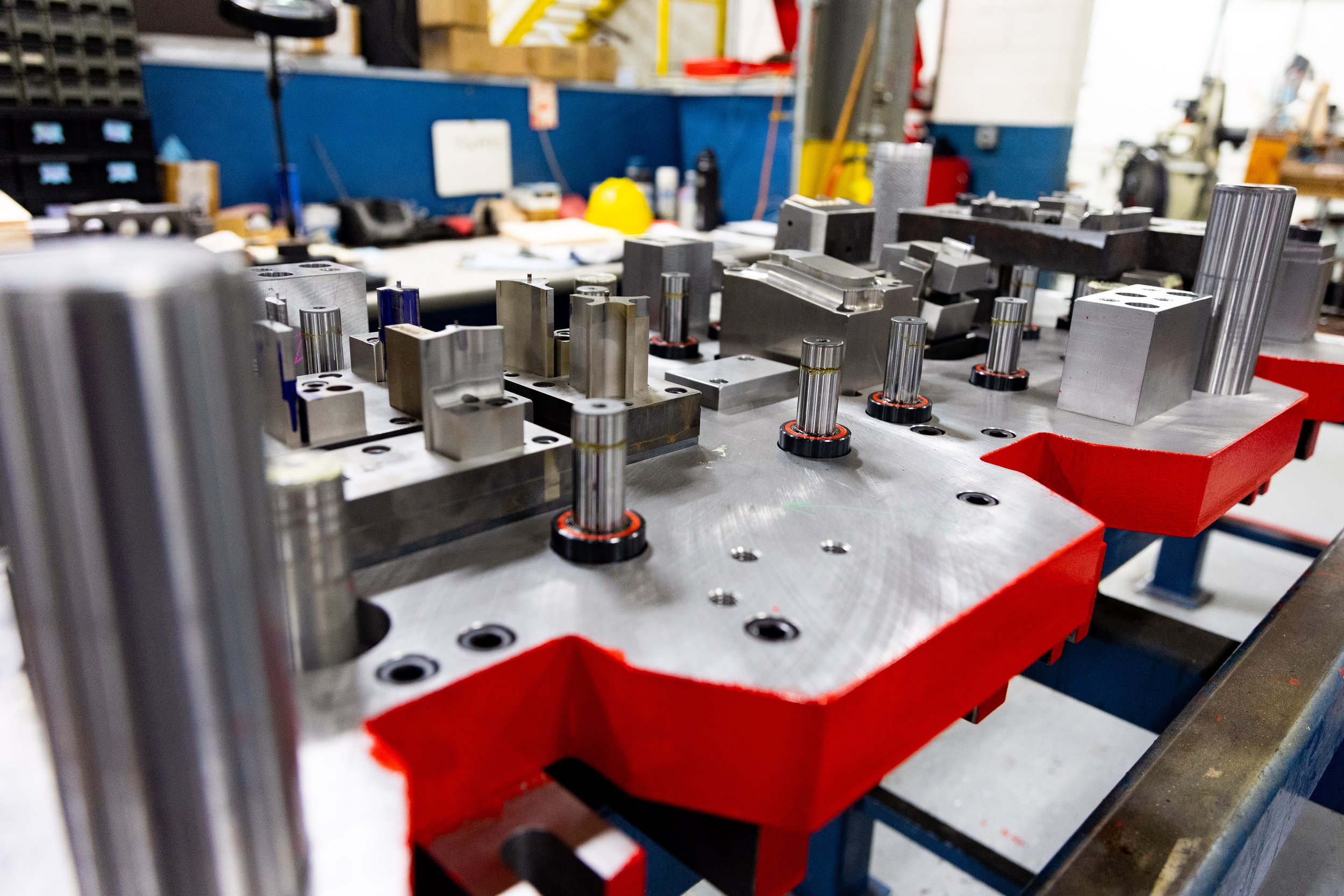

Tool Design & Build

-

Tool Design

PTM Corporation's investment in its tooling operations are substantial and, we believe it is essential to serving our customers. We are equipped with the most advanced 3D design software, CNC machining capability, wire EDM machines, automated grinding equipment and even production level presses dedicated to tool testing and try-out.

We produce:

Two, three and four piece kirksite dies

Progressive, compound, and line dies

Cost saving fourslide dies

Most of all we invest in our people. We employ skilled tool engineers/builders with all-encompassing stamping experience. We provide ongoing training and empower our employees to achieve the highest level of quality and efficiency.

-

Wire EDM

PTM Corporation's Wire EDM (Electrical Discharge Machining) department goes hand in hand with our commitment to technology. We currently have 5 Fanuc wire EDM machines complete with Erowa pallet systems. These pallet systems enable us to run lights out machining 24 hours a day, 7 days a week. These machines are used to cut the individual die details that will make up the completed stamping die, and form the part to shape.

EDM Machines create an electrical discharge between a thin wire or electrode and the work piece. As the discharge spark jumps across the gap, material is removed from both the work piece and the wire. A non conductive liquid prevents the process from shorting out and also flushes out the removed material. The result is a highly accurate and efficient process. We can wire EDM details as large as 14" x 20" x 12" thick.

Our Wire EDM machines are also equipped with the latest in Fanuc cutting software to ensure the fastest, most accurate wire technology available. This means faster turn around time for you, the customer. Don't forget to check out our wire EDM video!

-

CNC Machining

PTM Corporation’s CNC department consists of 10 machining centers. This offers the type of high-performance capabilities our customers expect. Additionally, PTM supplements state of the art proprietary software for these machines. This allows our designs to be sent directly to the shop floor for a truly seamless workflow.

Also, we utilize the latest in cutting tool technology. Specifically this gives us optimal performance in metal removal. Our equipment includes:

2 – Haas Super VF3 40″ x 20″

1 – Haas VM2 30″ x 15″

1 – Hartford 3 Axis 120″ x 80″ x 48″

1 – Hartford 3 Axis 80″ x 60″ x 48″

2 - Hartford 3 Axis 80" x 40" x 36"

1 – Kao Ming 3 Axis 78″ x 48″ x 36″

1 – Fadal 3 Axis 60″ x 30″ x 30″